|

Integral Spiral Blade Stabilizer

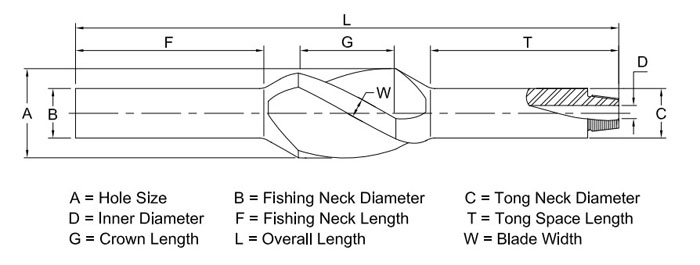

Tri Wave¡¯s IB Stabilizers are manufactured from AISI 4145H modified heat treated alloy steel, designed to be one-piece construction for a wide variety of specifications and hole sizes. The stabilizers can be run either near bit or up in the drill string.

Thanks to the various designs of hardfacing, Tri Wave¡¯s stabilizers are optimized tools in both drilling performances and economics cost, whatever in soft, medium or abrasive formations. |

|

Standard Specifications of IB Stabilizer

|

| Hole Size(in) |

Fishing Neck(Dia.in) |

ID(Dia.in) |

Fishing Length(in) |

Tong Length(in) |

Overall Length(in) |

Crown Length(in) |

Blade Width(in) |

| 6 |

4 3/4 |

2(21/4) |

34 |

20 |

73 |

16 |

2 |

| 6 1/4 |

| 6 1/2 |

| 7 1/2 |

6 1/4 |

2 1/4 |

34 |

20 |

75 |

18 |

2 1/2 |

| 7 7/8 |

| 8 3/8 |

6 1/4(6 1/2) |

2 1/4(2 1/2) |

34 |

32 |

86 |

18 |

2 1/2 |

| 8 1/2 |

| 2008/3/4 |

| 9 1/2 |

6 3/4 (7, 7 3/4) |

2 1/4(2 1/2) |

34 |

32 |

87 |

18 |

2 1/2 -2 3/4 |

| 9 5/8 |

| 9 7/8 |

| 12 1/4 |

8(8-1/4,9 1/2) |

2 13/16 |

36 |

36 |

95 |

18 |

3 |

| 14 3/4 |

8-1/4(9 1/2) |

2 13/16 |

36-40 |

34 - 36 |

98-101 |

18 |

3 1/4 |

| 16 |

9 1/2(8 1/2) |

2 13/16(3) |

36-40 |

36 |

103 |

18 |

3 1/2 |

| 17 1/2 |

| 24 |

9 1/2 |

2 13/16(3) |

40 |

40 |

120 |

18 |

4 |

| 26 |

| 28 |

Various Designs of Hardfacing

Tri Wave offers dedicated hardfacing meets different applications: |

|

Tungsten Hardfacing - dressing with crushed Tungsten in Nickel Bronze composite alloy rod with grinding. Depending on the toughness of the drilling formation, PREMIUM TUNGSTEN HARDFACING (dressing with 8-10 mesh Tungsten Rod) and HEAVY TUNGSTEN HARDFACING (dressing with 10-18 mesh Tungsten Rod) can be selected by customers.

Applied: Soft to Medium formation

Advantage: Economical cost and repairable |

|

SUPERHIGH TUNGSTEN TIPS Hardfacing - dressing with Tungsten inserts sintering by Tungsten carbide Nickel powder. It can get more strength and toughness after the welding procedure, to ensure the hardfacing’s abrasion resistance and not easily pull-out to cause damage.

Applied: High deviation drilling in abrasive formation

Advantage: Reliable wear, also repairable |

|

ULTRAHIGH TUNGSTEN Bricks Hardfacing- dressing with the combination of Tungsten inserts and crushed Tungsten carbide. It can get extreme high strength and toughness after the welding procedure, to ensure excellent abrasion resistance.

Applied: Most abrasive formation

Advantage: Most reliable wear |

|

Tungsten Carbide Inserts (button type) – one of the most traditional hardfacing using Tungsten carbide inserts button.

Applied: Soft to Medium formation

Advantage: Economical cost |

|